BBA online tuition, B.Com Online tuition, MBA online tuition, MBA projects and assignments solution

GM 04 Managerial economics assignment AIMA PGDM

Yes, I agree with the statement Because of economics of scale, it is

sometimes more cost effective for a firm to operate a large plant at less than

maximum efficiency than a small plant at maximum efficiency. Economies of scale

refer to the cost savings made possible as plant size increases. A firm is said

to achieve economies of scale if its long-run average costs decline as it

increases the size of its plant. All

costs are variable in the long run and they give rise to a long run cost curve

which is roughly L-shaped. In the beginning, the LAC curve rapidly falls but

after a point, the curve remains flat, or may slope gently downwards due to

benefits of economies of scale are neutralized after achieving a certain level

of production without reaching to its maximum production capacity.

Various reasons

attributed to LAC curve to be L shaped due to which it is cost effective to

produce less than maximum efficiency in a large plant than producing at maximum

efficiency in a small plant include-

1. Production and Managerial costs:

In the

long-run, all costs being variable, production costs and managerial costs of a

firm are taken into account when considering the effect of expansion of output

on average costs. As output increases, production costs fall continuously while

managerial cost may rise at very large scales of output. But the fall in

production costs outweighs the increase in managerial costs so that the LAC

curve falls with increases in output. We analyze the behaviour of production

and managerial costs in explaining the L-Shaped of the LAC Curve.

As a firm

increases its scale of production, cost fell steeply in the beginning and then

gradually. This is due to the technical economies of large scale production

enjoyed by the firm. Initially, these economies are substantial, but after a

certain level of output, when all or most of these economies have been

achieved, the firm reaches the minimaloptimal scale or minimum efficient scale (MES). Given the technology of the

industry, the firm can continue to enjoy some technical economies at outputs

larger than the MES for the following reasons.

(a) From

further decentralization and improvement in skills and productivity of labour.

(b) From lower

repair costs after the firm reaches a certain size; and

(c) By itself

producing some of the materials and equipment cheaply which the firm needs

instead of buying them from other firms.

In modern

firms, for each plant there is a corresponding managerial set-up for its smooth

operation. There are various levels of management, each having a separate

management technique applicable to a certain range of output. Thus, given a

managerial setup for a plant, its managerial costs first fall with the

expansion of output and it is only at a very large scale of output, they rise

very slowly.

In summary,

production costs fall smoothly at very large scales, while managerial costs may

rise slowly at very large scales of output. But the fall in production costs

more than offsets the rise in managerial costs so that the LAC curve falls

smoothly or becomes flat at very large scales of output, thereby giving rise to

the L-shape of the LAC curve.

Each SAC curve

includes production costs, managerial costs, other fixed costs and a margin for

normal profits. Each scale of plant is subject to a typical load factor capacity so that points A, B and C represent

the minimal optimal scale of output of each plant. By joining all such points

as A, B and C of a large number of SACs, we trace out a smooth and continuous

LAC curve.

2. Technical progress:

The L-shape of

the LAC curve due to technical progress can be explained using below figure:

Suppose the firm is producing 0Q1 output on LAC1 curve at per unit cost

of 0C1 output on LAC1 curve at a

per unit cost of 0C1. If

there is an increase in demand for the firm's product to 0Q2, with no change in technology, the firm will produce 0Q2 output along the LAC1 curve at per unit cost

of 0C'. If, however, there is technical

progress in the firm, it will install a new plant having LAC2 as the long-run average cost curve. On this plant,

it produces 0Q2 output at

a lower cost 0C2 per

unit. Similarly, if the firm decides to increase its output to 0Q3 to meet further rise in

demand, technical progress may have advanced to such a level that it installs

the plant with the LAC3

curve. Now it produces 0Q3

output at a still lower cost 0C3

per unit. If the minimum points, L, M

and N of these U-shaped long-run average cost curves LAC1, LAC2 and LAC3 are joined by

a line, it forms an L-shaped gently sloping downward curve LAC.

3. Learning:

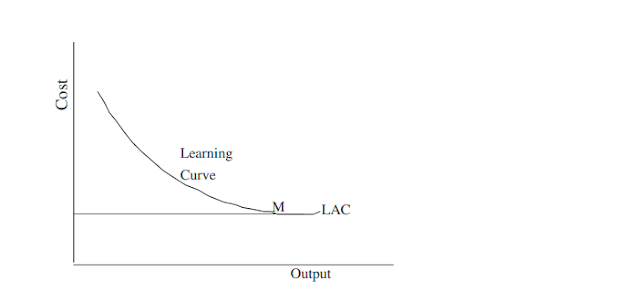

Yet another

reason for the L-shaped long-run average cost curve is the learning process.

Learning is the product of experience. If experience in this context can be

measured by the amount of a commodity produced, then higher the production is,

the lower it is per unit cost. The consequences of learning are similar to

increasing returns. First, the knowledge gained from working on a large scale cannot

be forgotten. Second, learning increases the rate of productivity. Third,

experience is measured by the aggregate output produced since the firm first

started to produce the product. Learning by doing has been observed when firm

starts producing new products. After they have produced the first unit, they

are able to reduce the time required for production and thus reduce per unit

cost. Growing experience with making the product leads to falling costs as more

and more of it is produced. When the firm has exploited all learning

possibilities, costs reach a minimum level.

Thus the LAC

curve is L-shaped due to learning by doing.

The planning of

the plant (or the firm) consists of deciding the size of the fixed and indirect

factors which determine the size of the plant, because they set limits to its

production capacity. Direct factors such as labour and raw materials are

assumed not to set limit on size; the firm can acquire them easily from the

market without any time lag. The business man will start his planning with a

figure for the level of output which he anticipates selling, and he will choose

the size of plant which allows him to produce this level of output more

efficiently, and with the maximum flexibility, the business man will want to be

able to meet seasonal and cyclical fluctuations in his demand. Reserve capacity

will give the business man greater flexibility for repairs of broken down

machinery without disrupting the smooth flow of the production process.

The

entrepreneur will want to have more freedom to increase his output if demand

increases. All businessmen hope for growth. In view of anticipated increase in

demand, the entrepreneur builds some reserve capacity because he would not like

to let all new demand go to his rivals as this may endanger his future hold in

the market. It also gives him some flexibility for minor alterations of his

product, in view of changing tastes of customers.

Technology

usually makes it necessary to build into the plant some reserve capacity. Some

basic types of machinery (e.g. a turbine) may not be technically fully employed

when combined with other small types of machines in certain numbers. More of

which may not be required, given the specific size of the chosen plant.

Furthermore, some machinery may be so specialized as to be available only on

order, which takes time. In this case, such machinery will be bought in excess

of the minimum requirement at present numbers, as a reserve.

Some reserve

capacity will always be allowed in the land and buildings, since expansion of

operations may be seriously limited if new land or new buildings have to be

acquired. Finally, there will be some reserve capacity on the organizational

and administrative level. The administrative staff will be hired at such

numbers as to allow some increase in the operations of the firm.

In summary, the

businessman will not necessarily choose the plant which will give him the

lowest cost, but rather, that equipment which will allow him the greatest

possible flexibility for minor alterations of his product or his technique of

production.